Welcome to the future, where 3D printing is revolutionizing the manufacturing industry. This blog post will delve into the transformative potential of 3D printing in manufacturing, exploring its current applications, future prospects, and the challenges it faces. We will also examine the impact of this technology on various sectors and its potential to reshape the global manufacturing landscape.

The Current State of 3D Printing in Manufacturing

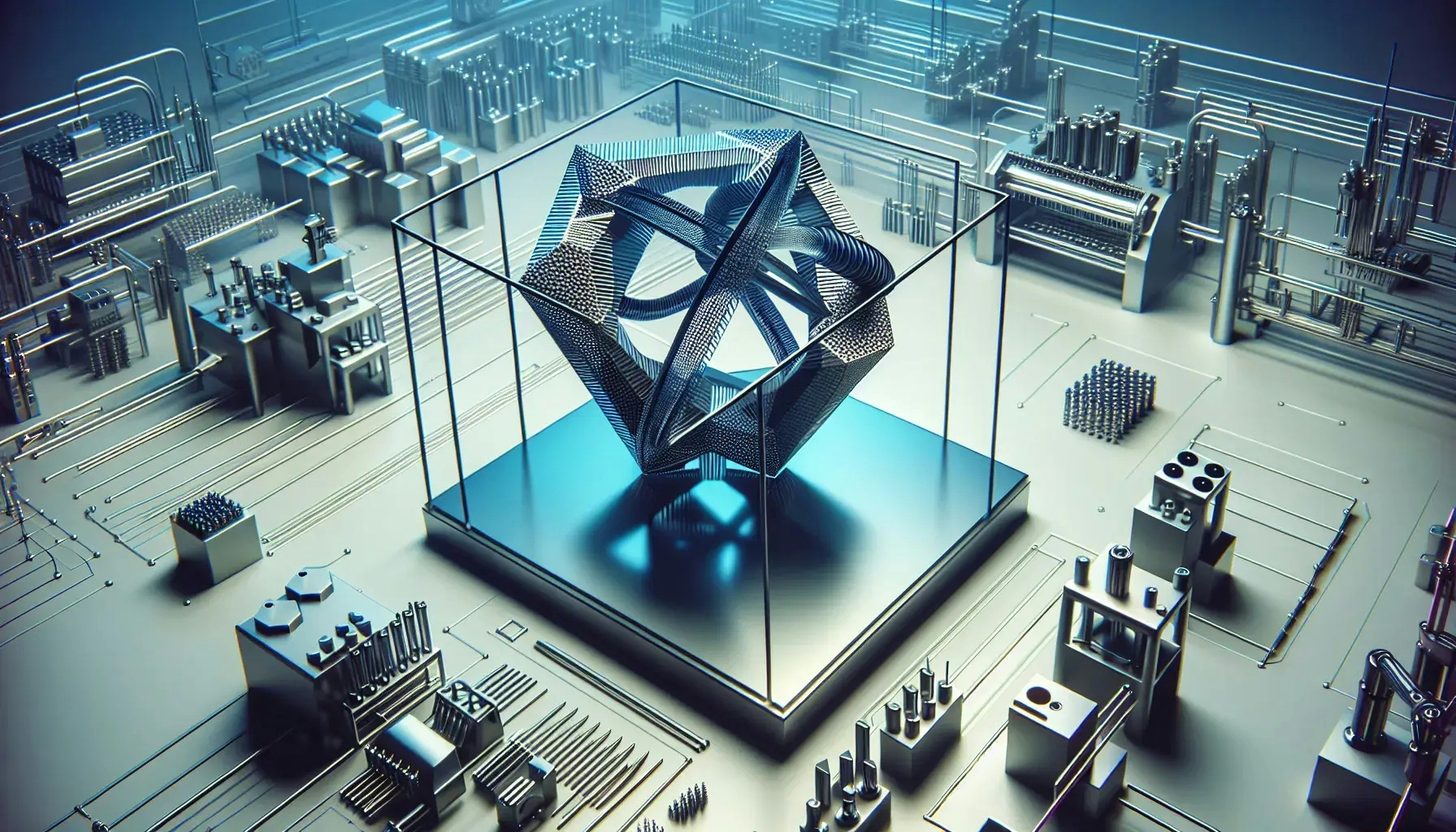

3D printing, also known as additive manufacturing, is not a new concept. However, its application in the manufacturing industry has gained significant momentum in recent years. Industries ranging from aerospace to healthcare are harnessing the power of 3D printing to create complex parts with precision and efficiency.

The beauty of 3D printing lies in its versatility. It allows for the production of customized parts on demand, reducing the need for large inventories. Furthermore, it enables the creation of intricate designs that would be impossible or prohibitively expensive with traditional manufacturing methods.

Despite these advantages, 3D printing currently represents a small fraction of the overall manufacturing industry. The technology is still in its developmental stages, with many companies experimenting with its potential. However, the trend is clear: 3D printing is on the rise, and its impact on the manufacturing industry is set to increase exponentially.

The Future Prospects of 3D Printing in Manufacturing

The future of 3D printing in manufacturing looks promising. As the technology matures, we can expect to see it integrated into more aspects of production. One area where 3D printing has significant potential is in the production of end-use parts. Currently, most 3D printed parts are used for prototyping. However, as the technology advances, we can expect to see more finished products being produced with 3D printers.

Another exciting prospect is the potential for localized production. With 3D printing, companies can produce parts on-site, reducing the need for long supply chains. This could revolutionize the way we think about manufacturing, shifting from a global to a local focus.

However, the future of 3D printing in manufacturing is not without its challenges. Issues such as the high cost of materials, limited material options, and the need for specialized skills can hinder the widespread adoption of the technology. Nevertheless, as these challenges are addressed, the role of 3D printing in manufacturing is set to grow.

Impact of 3D Printing on Various Sectors

The impact of 3D printing extends beyond the manufacturing industry. It has the potential to disrupt various sectors, from healthcare to construction. In the healthcare sector, 3D printing is being used to create customized prosthetics and implants, revolutionizing patient care. In construction, companies are experimenting with 3D printed buildings, potentially reducing construction time and waste.

The automotive industry is another sector where 3D printing is making waves. Companies are using the technology to produce lightweight, complex parts, improving vehicle performance and efficiency. In the aerospace industry, 3D printing is being used to create intricate components, reducing the weight of aircraft and improving fuel efficiency.

While these are just a few examples, they illustrate the transformative potential of 3D printing across various sectors. As the technology continues to evolve, its impact is set to broaden.

Challenges Facing the Adoption of 3D Printing in Manufacturing

Despite its potential, the adoption of 3D printing in manufacturing faces several challenges. One of the main hurdles is the high cost of materials. While the cost of 3D printers has decreased in recent years, the materials used in the process remain expensive. This can make 3D printing less cost-effective than traditional manufacturing methods for large-scale production.

Another challenge is the limited range of materials available for 3D printing. While advancements have been made, the range of materials that can be used in 3D printers is still relatively small compared to traditional manufacturing methods. This limits the types of products that can be produced using the technology.

Lastly, there is a need for specialized skills to operate and maintain 3D printers. This can pose a challenge for companies looking to adopt the technology, as it requires investment in training and development.

Overcoming the Challenges: The Way Forward

To overcome these challenges, several strategies can be employed. For the high cost of materials, research and development into cheaper, high-quality materials for 3D printing is crucial. This could involve collaborations between manufacturers, material suppliers, and research institutions.

In terms of the limited range of materials, advancements in technology could expand the types of materials that can be used in 3D printing. This would broaden the range of products that can be produced using the technology.

As for the need for specialized skills, companies can invest in training and development to equip their workforce with the necessary skills. This could involve partnerships with educational institutions to develop relevant training programs.

The Role of Policy in Shaping the Future of 3D Printing in Manufacturing

Policy also plays a crucial role in shaping the future of 3D printing in manufacturing. Governments can support the adoption of the technology through various means. This could involve funding for research and development, tax incentives for companies adopting the technology, and regulations that encourage the use of 3D printing.

Furthermore, governments can play a role in addressing the skills gap by investing in education and training. This could involve integrating 3D printing into the curriculum of technical and vocational education and training programs.

In conclusion, while there are challenges to the adoption of 3D printing in manufacturing, the potential benefits of the technology are immense. With the right strategies and policies in place, 3D printing could revolutionize the manufacturing industry, transforming the way we produce and consume goods.

The Dawn of a New Era: 3D Printing in Manufacturing

The future of 3D printing in manufacturing is bright. Despite the challenges, the potential benefits of the technology are immense. As we continue to innovate and overcome these hurdles, we can expect to see a shift in the manufacturing landscape. The dawn of a new era in manufacturing is upon us, and 3D printing is at the forefront of this revolution.